Forged & Cast Steel Valves

Alyamitech supplies Cast & Forged Steel Valves from Bonney Forge like gate valves, globe valves, cryogenic valves, integrated flanged end valves, bellows sealed valves, trunnion ball valves, double block & bleed valves in Saudi Arabia.

Alyamitech supplies Bonney Forge products in Saudi Arabia, serving the needs of diverse industries with precision-engineered valve solutions. Forged Steel Valves includes high-quality forged steel gate and globe valves, cryogenic valves, and advanced ball valve variants, all designed to handle the toughest operational challenges.

By partnering with Bonney Forge, renowned for their cutting-edge manufacturing and durability, we ensure that each product delivers exceptional performance, reliability, and safety. Our commitment to quality and technology enables us to provide solutions that support the successful execution of complex infrastructure projects throughout Saudi Arabia.

Forged Steel Gate Valve

Bonney Forge, a prominent manufacturer of forged steel gate valves, offers two distinctive bonnet designs. The Bolted Bonnet features a male-female joint, spiral wound gasket in F316L/graphite, and optional ring joint gaskets. Meanwhile, the Welded Bonnet Gate Valve includes a threaded and seal welded joint, with the option for a full penetration strength welded joint upon request. These designs ensure durability and reliability, catering to various industrial needs.

These gate valves are ideal for on-off services, providing a straight-line fluid flow with minimal restriction. The gate valve operates by either halting or permitting flow, resembling the motion of opening or closing a gate, hence its name. When fully open, the closure member retracts, allowing unimpeded flow and minimal pressure drop. Widely used in industries such as oil and gas, pharmaceuticals, manufacturing, automotive, and marine, these valves are unsuitable for throttling but excel in their core function.

Forged Steel Globe Valve

Forged steel globe valves by Bonney Forge are essential for flow regulation and frequent operation. Designed as closing-down valves, they feature a closure member moving squarely on and off the seat, allowing the seat opening to vary in direct proportion to the disc travel. This design is optimal for flow rate regulation and effective on-off duties, ensuring high sealing capacity.

The valves offer a standard Straight “T”-Pattern with higher flow resistance, and an oblique pattern for reduced resistance. Ideal for industries like oil and gas, pharmaceuticals, and manufacturing, these valves are perfect for frequent operations requiring positive shut-off.

Forged Steel Cryogenic Valve

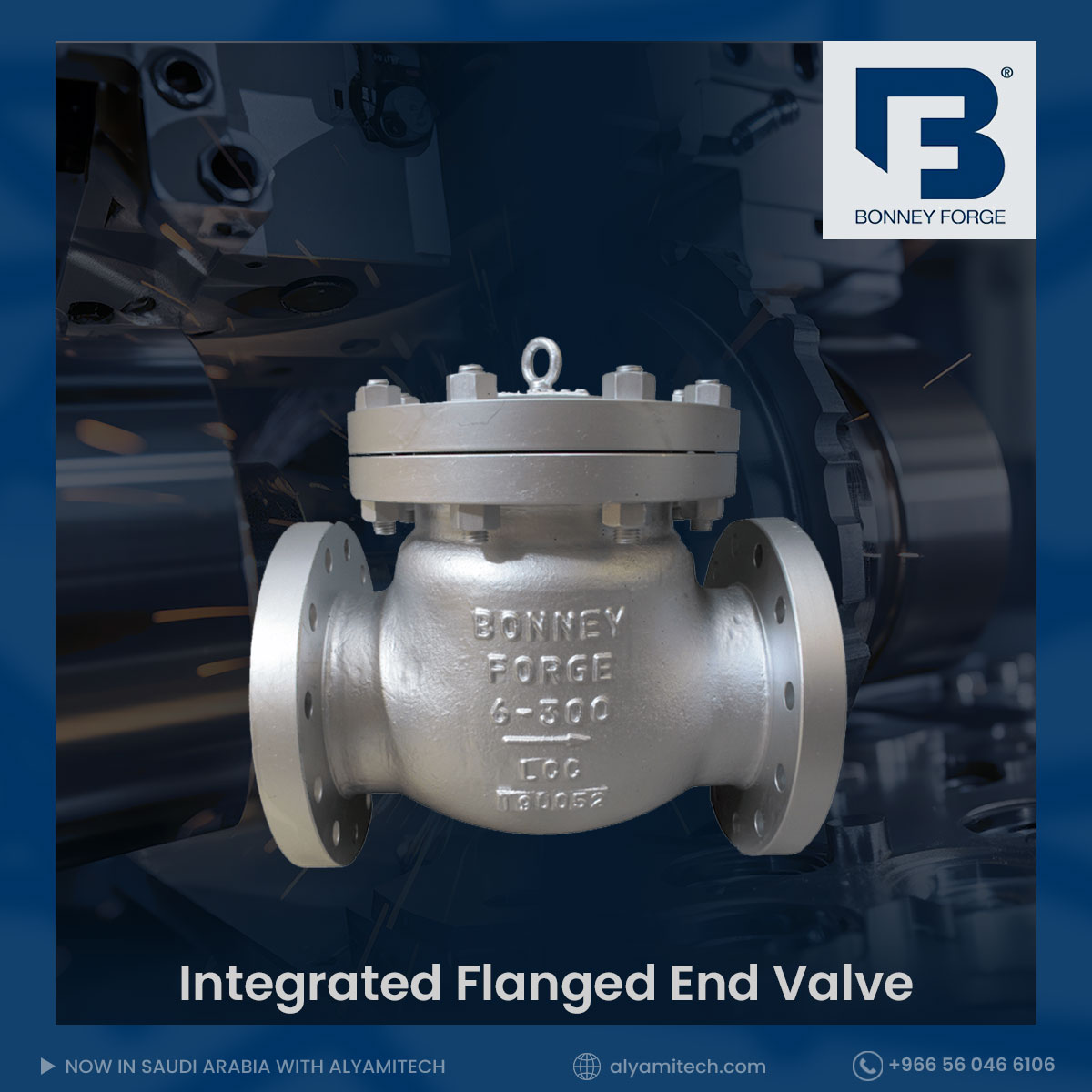

Integral Flanged End Valve

Integral flanged end valves from Bonney Forge are available in two bonnet designs. The Bolted Bonnet features a male-female joint and spiral wound gasket made of F316L/graphite, with optional ring joint gaskets. The Welded Bonnet comes with a threaded and seal welded joint, with an option for full penetration welding.

These valves are available in gate, globe, piston check, ball check, and swing check configurations, ranging from class 150 to class 2500.

Forged Steel Bellows Sealed Valve

Bonney Forge valves offer two distinct bonnet designs. The Bolted Bonnet Bellows Sealed Valves features a male-female joint and a spiral wound gasket made from F316L/graphite, with the option of a ring joint gasket. The second design is the Welded Bonnet, providing a threaded and sealed welded joint, with an option for a full penetration strength welded joint available upon request.

For specialized applications, Bonney Forge provides bellows sealed valves in both gate and globe valve configurations. These designs ensure reliable performance, making them a trusted choice for demanding environments.

Extended Body Gate Valve

Bonney Forge extended body gate valves come in two bonnet designs. The Bolted Bonnet features a male-female joint and spiral wound gasket made from F316L/graphite, with an optional ring joint gasket. The Welded Bonnet offers a threaded and seal-welded joint, with a full penetration strength welded joint available on request.

These valves are available as class 800 and class 1500 extended body forge gate valve, catering to various pressure requirements.

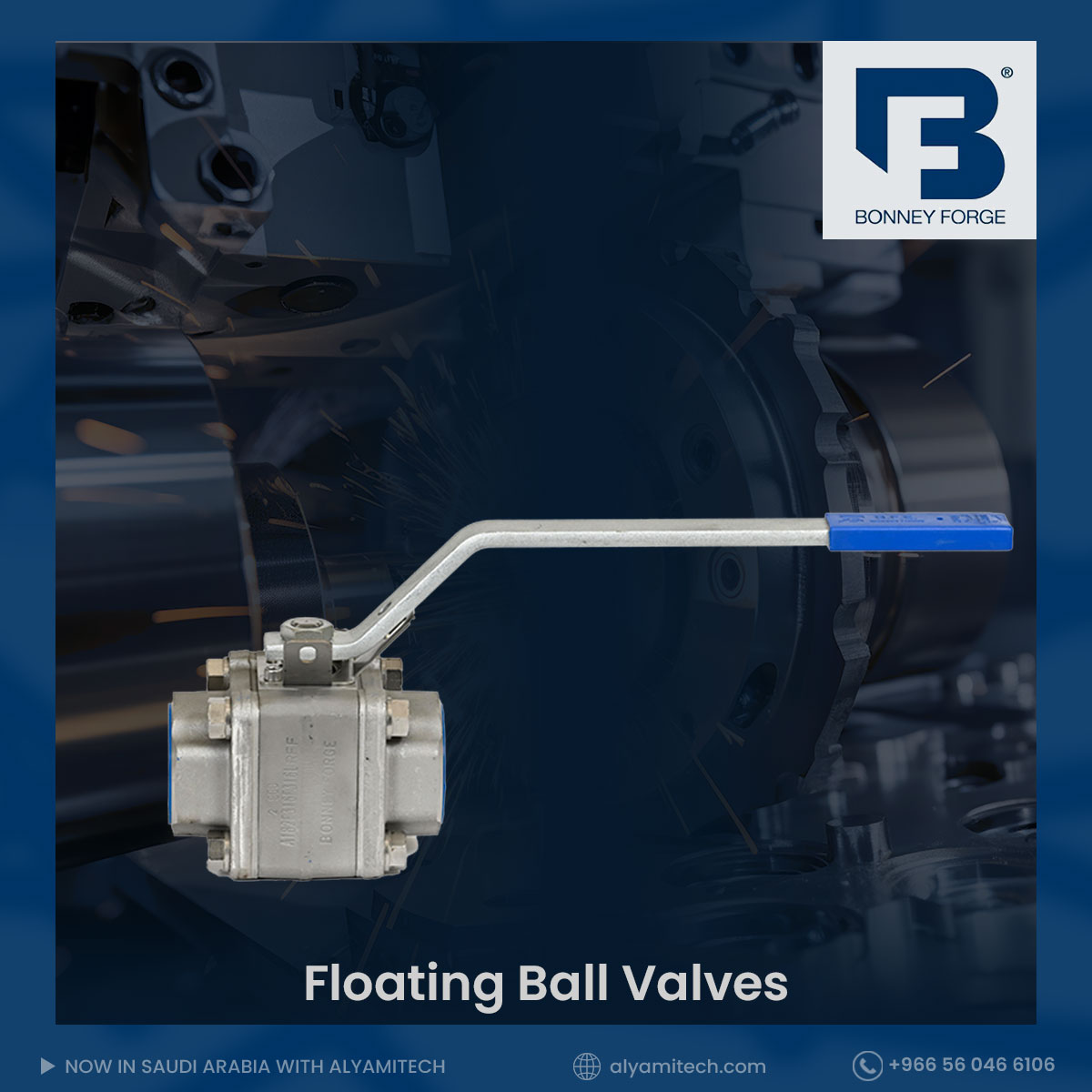

Floating Ball Valves

Forged floating ball valves, a type of quarter-turn valve, use a pivoting sphere to regulate flow. Natural line pressure forces the ball against the downstream seat, ensuring a secure seal. This design allows for opening when the ball aligns with the flow and closing when rotated 90-degrees.

Due to their durability and reliability, floating ball valves excel in shut-off applications over gate and globe valves. They offer ease of operation, repair, and versatile industrial use, performing consistently even after extended disuse.

Typically, floating ball valves support bi-directional shut-off. However, larger valve bores amplify line pressure, demanding alternative designs due to increased force on the ball. These valves suit medium-sized, low-pressure setups, yet aren’t ideal for throttling.

Trunnion Ball Valves

Forged trunnion ball valves are ideal for on/off service in large and high-pressure settings due to their anchored ball design. Bonney Forge offers diverse designs, materials, sizes, pressure classes, and end connections, aligned with ASME B16.34 and applicable API or BS standards.

These fire-safe test-approved valves provide features ensuring electrical continuity between ball, stem, and body. Available in cryogenic and high-temperature metal seated configurations, all designs are forged for enhanced mechanical properties, pressure retention, and quality, making them reliable and durable for demanding applications.

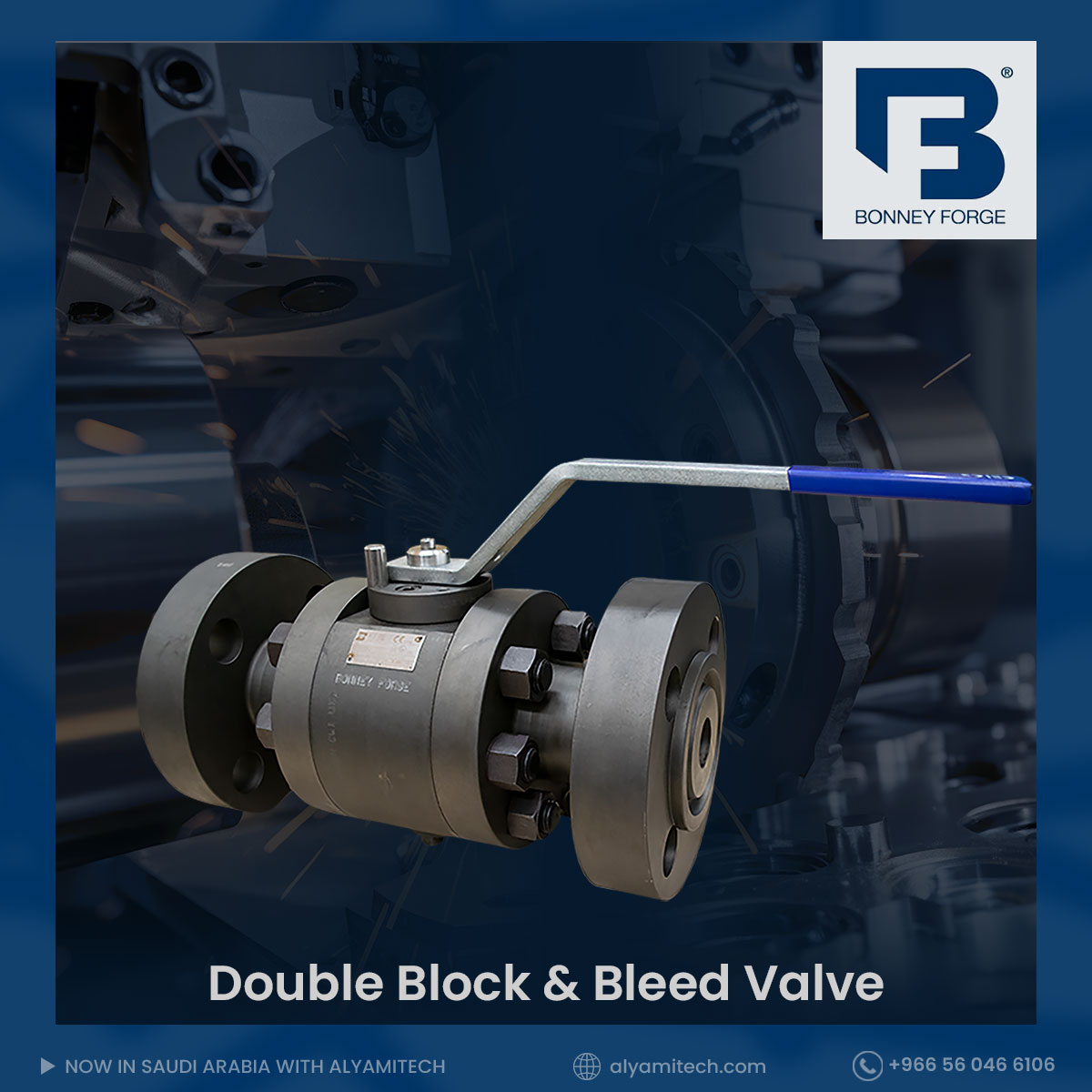

Double Block & Bleed Valves

Bonney Forge provides a diverse selection of Double Block and Bleed Valves (DBB valves), available in various designs, materials, sizes, and pressure classes, conforming to ASME B16.34 and applicable API or BS standards. These valves boast fire-safe certification and offer secure electrical connections between components. They come in cryogenic and high-temperature metal-seated variants, with all models forged to enhance mechanical properties, pressure integrity, and quality.

Key Applications for DBB Valves:

- Instrumentation in chemical injection and sample collection.

- Pressure gauge isolation via double block and bleed.

- Process isolation through in-line double block and bleed.

Advantages of Bonney Forge DBB Valves:

- Enhanced Safety: Minimizes leak points compared to conventional methods.

- Cost Efficiency: Integrates bleeding, reducing the need for extra piping.

- Space and Weight Optimization: Lessens stress from load and vibration.

Bonney Forge products, distributed by Alyamitech, stand as a benchmark for excellence in Saudi Arabia’s industrial valve market. With a focus on precision, durability, and advanced technology, these valves enhance operational efficiency and safety, ensuring robust performance in even the most demanding applications across varied infrastructure projects.